All Categories

Featured

Table of Contents

- – Professional Hood And Duct Cleaning Alhambra, CA

- – Instant Air Solutions

- – Commercial Kitchen Hood Service Alhambra, CA

- – Commercial Kitchen Hood Installation Alhambra, CA

- – Professional Hood And Duct Cleaning Alhambra, CA

- – Kitchen Hood Repair Near Me Alhambra, CA

- – Restaurant Hood Cleaning Near Me Alhambra, CA

- – Hood Filter Cleaning Alhambra, CA

- – Restaurant Ventilation Cleaning Alhambra, CA

- – Kitchen Hood Repair Near Me Alhambra, CA

- – Fire Suppression System Inspection Alhambra, CA

- – Kitchen Hood Inspection Alhambra, CA

- – Kitchen Hood Inspection Alhambra, CA

- – Fire Suppression System Inspection Alhambra, CA

- – Kitchen Hood Service Alhambra, CA

- – Instant Air Solutions

Professional Hood And Duct Cleaning Alhambra, CA

Exhaust hoods can be classified based on their applications and installment configurations. At NFP, we use top-grade range hoods for any type of application and arrangement.

These hoods can not manage oil, so they're mounted above ovens, cleaners, and any type of various other non-grease-producing devices. Type II hoods remove heat, vapor, and odors from the air and give a much more comfortable atmosphere.

Commercial Kitchen Hood Service Alhambra, CA

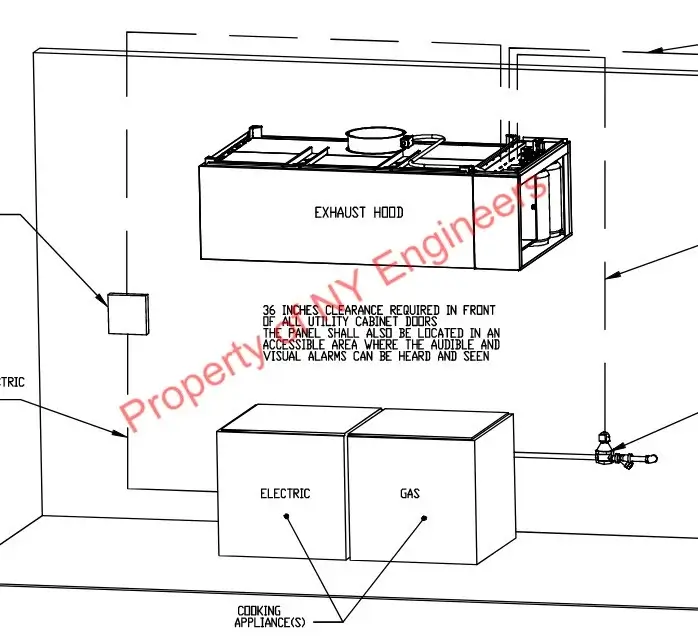

In industrial cooking areas, it prevails that some cooking home appliances are put in the facility of the cooking area, not versus a wall. So, hoods (type I, II, and ventless) are put on hold from the ceiling right over the food preparation tools to give effective protection - Kitchen Exhaust Cleaning Alhambra. Appropriate installation and thinking about great structural assistance are vital to ensure the hood is safely connected and can be used without any kind of problem

They're placed closer to the surface area of the cooking devices for an extra efficient exhaust of oil vapors and harmful fumes. Likewise, they often tend to take much less area and this has made them a wonderful choice for places with limited room, such as food trucks.

Because of this buildup, most restaurant cooking areas mount a kitchen area hood. Alturas contractors assist you do simply that, with a group of hood installers in Los Angeles.

Commercial Kitchen Hood Installation Alhambra, CA

Below are several of the indicate consider before you speak to a handyman for hood installation. If you are a brand-new restaurant proprietor, and trying to find business hood installation firms near you in Los Angeles, this list will certainly aid you discover the right one. Make certain to work with certified specialists that comprehend dining establishment ventilation systems.

Hire somebody that already has experience with the leading commercial hood brand names that you are taking into consideration. Safety is one of the important elements to consider for Kitchen area ventilation.

To stay clear of grease fires, Kind 1 cooking area hoods have to be cleansed regularly. The condensate hoods are also recognized as Type 2 Industrial cooking area Hoods.

Professional Hood And Duct Cleaning Alhambra, CA

Condensate hoods do not include a grease filter and are generally manufactured from galvanized air ducts rather than bonded. The exhaust air flow and just how it's taken care of are important considerations. Installation prices for a ductless system are reduced than for an aired vent exhaust-style system with ductwork, depending upon the exhaust air flow system you select.

As a result, they're less pricey than a Type I hood with an exhaust system. A system like this must not be used in a cooking area that produces a great deal of oil.

Specialist setup of ventilation systems, including cooking area hoods and industrial hoods, is vital to guarantee proper airflow and security in commercial cooking areas. The hood installation process includes mindful preparation and adherence to regional codes, and it calls for professional expertise to mount an industrial cooking area ventilation system correctly.

If you are based anywhere near or in Los Angeles, our group of cooling and heating service technicians is just one phone call away. We offer a listing of air flow services in restaurants, offices, grocery stores, and medical facilities. Feel complimentary to obtain in touch with us for business hood setup estimates. The commercial cooking area hood installment expense differs relying on the size, product, labor, and location.

Kitchen Hood Repair Near Me Alhambra, CA

Mounting a hood system in a restaurant on your very own might not be the very best idea. We suggest you call business hood installation companies to help you. Professional service providers should be hired considering that they have the appropriate devices and experience. Poor setup could lead to poor interior air extraction to the outside, reducing the unit's efficiency.

With the aid of a professional kitchen area hood installer or a/c professional, setting up a kitchen hood for a restaurant should not take longer than 60 mins. However, in many cases, depending upon the demands in an industrial configuration, it could take much longer. It is best to speak with a technician for an on-site price quote prior to air vent hood or array hood setup.

They need to also consist of: Fire suppression systemsGrease filtersExhaust followers with ductwork These hoods are used for home appliances that produce warmth or vapor however not grease, such as dishwashers and stoves. They do not have fire suppression however call for reliable air capture.

: These are the most typical sort of industrial cooking area exhaust hoods, normally linked to the wall surface over the range and aired vent outside. Made of stainless-steel, they are sturdy and personalized for any type of kitchen area layout.: Suspended from the ceiling above an island or free standing cooktop, these hoods need more powerful ventilation and tend to be extra expensive because of their architectural requirements.: The least common in commercial setups, these are installed under a cupboard or kitchen counter.

Restaurant Hood Cleaning Near Me Alhambra, CA

When installing a cooking area hood, it's critical to make use of corrosion-resistant ductwork that holds up against the oily and moist kitchen area environment. All electrical components should be GFCI-protected to enhance safety. Furthermore, ensure the ductwork design enables very easy accessibility for regular maintenance and cleaning - Kitchen Exhaust Cleaning Alhambra. Many states now call for that all fire suppression systems be, making use of damp chemical representatives particularly designed for grease fires.

Before installation, it is essential to coordinate with the local fire marshal and structure division. Prepare and submit a comprehensive MEP (Mechanical, Electric, Plumbing) plan to facilitate a smooth allowing procedure and make certain neighborhood code conformity. To keep ideal performance, clean oil filters at least once a week, or a lot more frequently depending on cooking volume.

Hood Filter Cleaning Alhambra, CA

Explore our resort kitchen area solutions or call us to start. A is required for appliances that generate grease and smoke (e.g., fryers, grills, griddles). are utilized for appliances that produce warm or heavy steam yet no grease, such as ovens or dish washers. Constantly examine regional fire and structure codes for specific requirements.

Generally of thumb, the hood ought to of the devices and give ample airflow for effective ventilation and code conformity. have to include a, developed specifically for grease fires. These systems need to be professionally in conformity with guidelines.

All restaurants, whether they are industrial chain dining establishments or any type of family-owned walk-in restaurants must carry out procedures to take care of air movement far better. Business kitchen ventilation systems likewise called restaurant hoods play a critical function in effectively flowing the air within cooking locations. Their main objective is to properly remove smoke and odours that are created during the cooking procedure.

Restaurant Ventilation Cleaning Alhambra, CA

It can be challenging to figure out the excellent place, installing the ventilation hood, and linking the ductwork. These industrial kitchen hoods are all necessary components of your commercial kitchen air flow system.

There are 2 key factors why you would certainly need to install a Dining establishment hood. The first is to change an old restaurant hood, and the second is to component of a brand-new commercial dining establishment hood system you are setting up. Whatever your inspiration for installing a new restaurant hood, the a lot more ready you are, the easier your setup will be.

Kitchen Hood Repair Near Me Alhambra, CA

It is essential to always consider hiring a licenced specialist when repairing the Restaurant Hood. In many cases, an incompetent setup could potentially invalidate the warranty terms. Afterwards, you have to put the restaurant hood in a room large enough to lay duct with couple of barriers and away from flammable items.

You must think about using protective goggles, steel-toed shoes, gloves, and earmuffs to reduce the danger of any type of kind of injury. When you have actually obtained the totally secured Dining establishment hood installment, it is very important to unload it with caution. Take treatment to prevent bending, damaging, or nicking any part of the hood during the unboxing procedure.

For that, check the nameplate specifications and the billing for all other components to guarantee you obtained the best equipment. If difficulties develop, call the maker. Prior to mounting, evaluate the restaurant hood layout for manufacturing facility designs. To place the dining establishment hood assembly according to the last design, you can utilize the floor.

These modifications need to be made by the specs given in the hood weight index, which can be discovered in the installment handbook. Make use of a 1/2-inch threaded pole mounted to the roofing structural beams for hanging the dining establishment hood. Use a power motorist to drill 9/16-inch openings right into the roof covering structural beams, straightening with the air flow hood's tilted mounting braces.

Fire Suppression System Inspection Alhambra, CA

Install a 1/2-inch threaded rod in between mounting brackets on the ventilation hood and architectural light beams. Secure the pole making use of fender washers and nuts. Bonded the exhaust air duct to the air flow hood while it gets on the floor. Ensure a total weld to protect against leakages, including at the connection point in between the restaurant hood and exhaust collar.

Placement the 1/2-inch threaded rods regarding 1/2 inch closer to the back wall top wall mount to align the ventilation hood flush versus the wall surface. Verify that the air flow hood hangs level.

Practical for you: Total Restaurant Air Flow System Guide It is for certain that your commercial restaurant hood will constantly come with an entire set of comprehensive guidelines from the manufacturer to let you understand how to install a restaurant hood. While managing your fan, attempt not to raise it by the fan hood.

Attempt to manage it with treatment to stop damage to both your follower along with your roof. In instance you already do not have actually one mounted, you will require to set up a roofing system visual all from the ground up. Follow the producer's standards and guidelines for safeguarding the curb to the roof.

Kitchen Hood Inspection Alhambra, CA

During the procedure of installation, you may initially need to make certain that your power resource works with the needs of your industrial dining establishment hood. Always try to make sure that you always disconnect the power supply prior to starting any job on or near a dining establishment hood. It would constantly be a good concept to protect the power cable to stay clear of any unintentional call with sharp things or devices.

This suggests that you might invest much more than the price estimated above if you are taking into consideration a high-end commercial range hood for your kitchen. Additionally, the quantity of food preparation you would plan to do would also help to determine the equipment you require to purchase for your kitchen. You can constantly choose to opt for a general-purpose commercial range in situation you intend to do a great deal of cooking and cooking which can cost anywhere between $1100 and $10,000.

Kitchen Hood Inspection Alhambra, CA

However, to clean your kitchen area air most efficiently, purchase a ducted variety hood. As opposed to move the food preparation exhaust, it will certainly leave it from your home entirely. As a whole, the majority of installations need a distance from 20 to 24 in between all-time low of the hood and the food preparation surface area. Over a gas range, this range ought to be between 24 and 30, unless or else defined.

Then, make use of a degreasing solution to clean surfaces, wash thoroughly, and reinstall filters.

Fire Suppression System Inspection Alhambra, CA

When doubtful, consult with an industrial cooking area specialist. A kitchen area hood have to be set up directly over the food preparation devices, but the exact positioning depends on the hood design and the home appliances under it. Your regional code might define a minimum and maximum elevation. As soon as you've selected your commercial kitchen area hood, you need to acquire it in addition to any needed setup equipment.

Begin by noting the location where the hood will certainly be installed. See to it the hood is flawlessly leveled. Use mounting braces to protect the hood to the wall surface or ceiling, depending on your style. It's recommended to have an expert or a person with solid DIY abilities do this. The ductwork connects the hood to the exhaust follower.

Make certain the air ducts are set up to air vent the exhaust air beyond the structure. The exhaust fan needs to be installed on the exterior wall surface or roof covering, and linked to the ductwork coming from the hood. Ensure it's set up effectively so that it effectively gets rid of smoke, warmth, and odors.

Bear in mind, these are general steps and may vary based upon the specific sort of hood and regional laws. Constantly talk to an expert if you're unclear. And always remember, safety and security should constantly be the very first concern. In the process of establishing a commercial cooking area, you'll undoubtedly come across the requirement for a commercial-grade ventilation hood.

Kitchen Hood Service Alhambra, CA

Installing an industrial cooking area hood is a task that should not be tried without specialist support. The journey towards installation should commence with a consultation with an expert hood supplier.

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: [email protected]

Instant Air Solutions

Insufficient installation could trigger air leakages, endangering the hood's performance and possibly developing fire dangers. By working together with seasoned specialists, you can guarantee your hood is set up to adhere to market criteria and finest methods. The industrial kitchen hood installation procedure involves a number of crucial actions. The installer installs the hood to either the ceiling or wall surface.

Commercial Kitchen Ventilation Services Alhambra, CAHood Filter Replacement Alhambra, CA

Commercial Kitchen Hood Cleaning Alhambra, CA

Commercial Kitchen Ventilation Alhambra, CA

Commercial Kitchen Ventilation Alhambra, CA

Kitchen Exhaust Cleaning Alhambra, CA

Kitchen Exhaust Fan Motor Replacement Alhambra, CA

Commercial Kitchen Hood Installation Alhambra, CA

Commercial Kitchen Hood Installation Alhambra, CA

Kitchen Exhaust Fan Motor Replacement Alhambra, CA

Kitchen Exhaust Fan Motor Replacement Alhambra, CA

Kitchen Exhaust Fan Motor Replacement Alhambra, CA

Professional Hood And Duct Cleaning Alhambra, CA

Kitchen Exhaust Cleaning Service Alhambra, CA

Restaurant Kitchen Ventilation Alhambra, CA

Kitchen Hood Repair Service Alhambra, CA

Kitchen Exhaust Cleaning Alhambra, CA

Restaurant Ventilation Cleaning Alhambra, CA

Restaurant Ventilation Cleaning Alhambra, CA

Kitchen Exhaust Fan Repair Service Alhambra, CA

Hood Filter Cleaning Alhambra, CA

Commercial Kitchen Ventilation Services Alhambra, CA

Kitchen Hood Repair Near Me Alhambra, CA

Fire Suppression System Certification Alhambra, CA

Commercial Kitchen Ventilation Alhambra, CA

Commercial Hood Installation Alhambra, CA

Hood Vent Cleaning Services Alhambra, CA

Professional Hood And Duct Cleaning Alhambra, CA

Commercial Hood Cleaning Service Alhambra, CA

Hood Cleaning Companies Alhambra, CA

Commercial Kitchen Hood Installation Alhambra, CA

Kitchen Exhaust Cleaning Service Alhambra, CA

Kitchen Hood Grease Removal Alhambra, CA

Near Me Top Seo Company Alhambra, CA

Best Seo Services Alhambra, CA

Instant Air Solutions

Table of Contents

- – Professional Hood And Duct Cleaning Alhambra, CA

- – Instant Air Solutions

- – Commercial Kitchen Hood Service Alhambra, CA

- – Commercial Kitchen Hood Installation Alhambra, CA

- – Professional Hood And Duct Cleaning Alhambra, CA

- – Kitchen Hood Repair Near Me Alhambra, CA

- – Restaurant Hood Cleaning Near Me Alhambra, CA

- – Hood Filter Cleaning Alhambra, CA

- – Restaurant Ventilation Cleaning Alhambra, CA

- – Kitchen Hood Repair Near Me Alhambra, CA

- – Fire Suppression System Inspection Alhambra, CA

- – Kitchen Hood Inspection Alhambra, CA

- – Kitchen Hood Inspection Alhambra, CA

- – Fire Suppression System Inspection Alhambra, CA

- – Kitchen Hood Service Alhambra, CA

- – Instant Air Solutions

Latest Posts

Ductless Air Conditioner Tujunga

Sherman Oaks Swamp Cooler Water Line Repair

Hood Filter Cleaning Pacoima

More

Latest Posts

Ductless Air Conditioner Tujunga

Sherman Oaks Swamp Cooler Water Line Repair

Hood Filter Cleaning Pacoima